We develop and produce top quality reliable etched foil elements for heating surfaces and fluids through excellent heat exchange and thermal uniformity, generally with lower temperatures than those on other heaters.

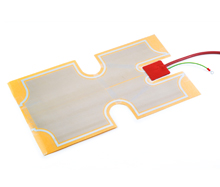

Etched foil heating elements come from printed circuit technology. They comprise a slim metal heating track (in aluminium, steel, nickel-chrome non-magnetic alloys, copper, constantan, etc.) between two insulating sheets of silicone, polyester, polyimide or mica.

They are supplied complete with:

- Wires with PVC, silicone, polyimide, Teflon, etc. protection

- Connectors.

- Controls such as thermostats and thermal fuses.

- Sensors: thermocouples, PT100, PT1000, NTC, SMD components.

- ZIF connections.

In the early nineties we developed this technology to meet the specific needs of technologically advanced industries such as aerospace, telecommunications and aeronautics.

Through time our laboratories have tested versatility of this technology and nowadays we co-design with our customers bespoke etched foil heating elements for many other applications.

Flat heating elements offer a series of advantages that make them one of the most effective solutions not only in hi tech industries:

- Possibility to differentiate power distribution locally to offset possible lack of thermal consistency.

- Minimum heat dispersion for applications on external surfaces to be heated.

- Possibility to provide shapes and extremely versatile contours in terms of extension and complexity.

- Flexible and easy to fit.

- Minimum weight and thickness.

- Overall savings on many applications.

The quality of our company processes is certified by UNI EN ISO 9001:2008 and BS EN 9100:2009.

Processes used for etched foil heating elements for the aerospace industry are ESA certified to ESCC 4009 and 4009/002 specifications.

Flat heating elements are UL and VDE certified and have protection rating IP67.